TPFL® Thermoplastic COMPOSITE

The textile solution for thermoplastic composites offering:

- Void-free Composites

- High Drapability allowed by supple non-consolidated textures

- Extreme conformability to complex geometries allowed by the stretch broken fibers

- Porosity-free Composites

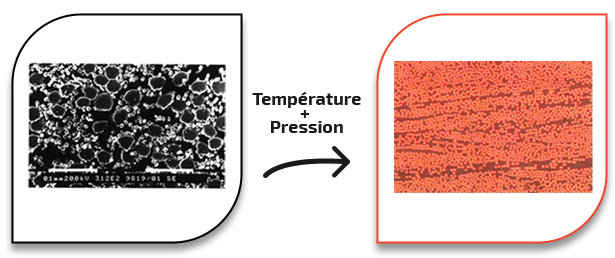

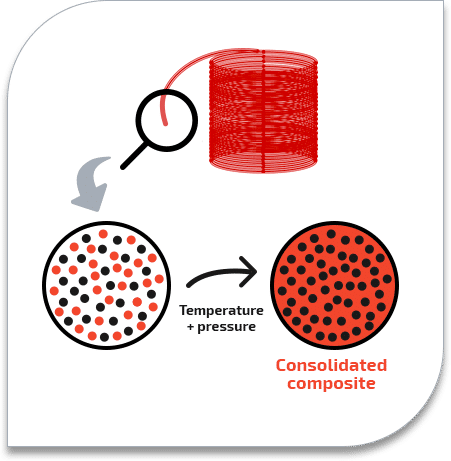

Porosity-free Composites

The true intimate blend made during the production of the TPFL® yarns, that is only possible due to the use of stretch-broken fibers, drives to very short distance between the polymer fibers and reinforcements fibers.

This allows a quick wet out of the reinforcement fibers during the composites consolidation, driving to absence of porosity in the parts, driving to very reproducible high performances.

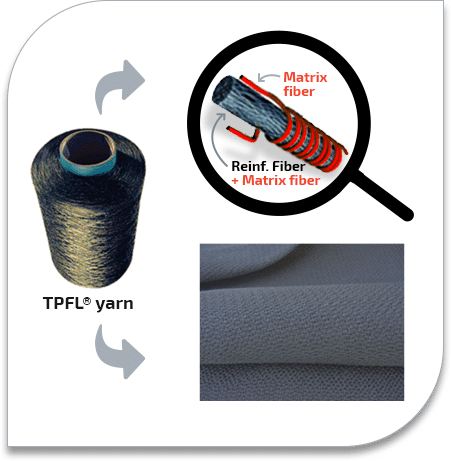

High Drapability

Since the polymers are not melted during the production of the TPFL® yarns, these ones remain very flexible, same as the textures (Fabrics, braids or knits) that can be done from those. Therefore, the layup is eased, in particular for complex geometries.

The goal : « A drapable prepreg which can be consolidated in a short time for the production of high performances parts. »

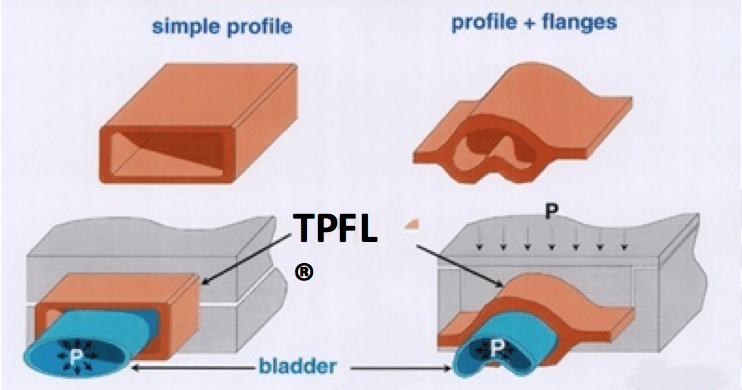

Conformabilité

Since the reinforcement fibers are discontinuous, the TPFL® yarns are able to be elongated and to conform to the geometry of the part to produce, this feature being unique on the market. During the consolidation, the melted polymer is easing the slide of the reinforcement fibers, allowing the production of parts with complex geometries or even non-developable shapes.

The TPFL® intimate blend

Details of the TPFL® yarn

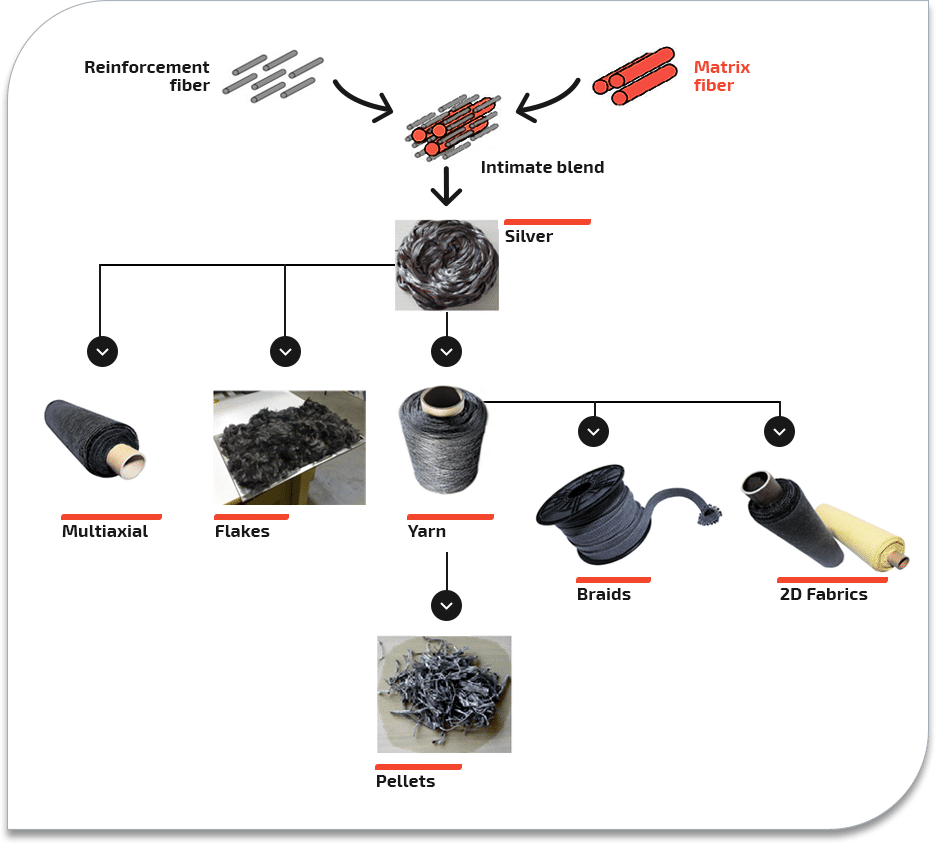

TPFL® product range

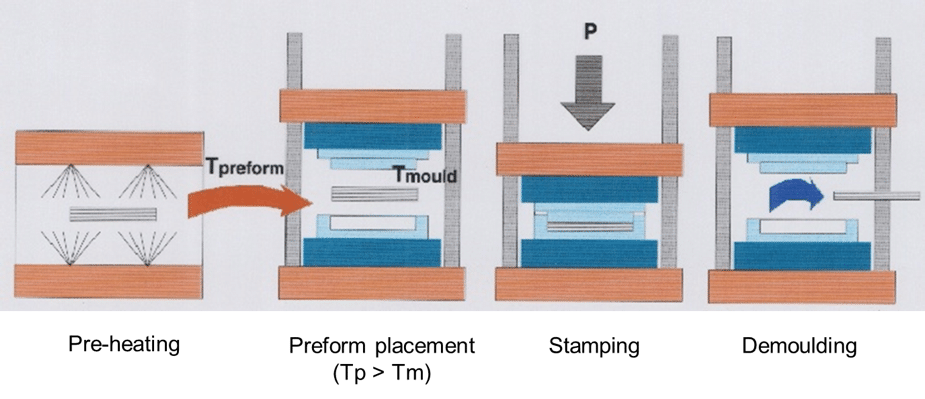

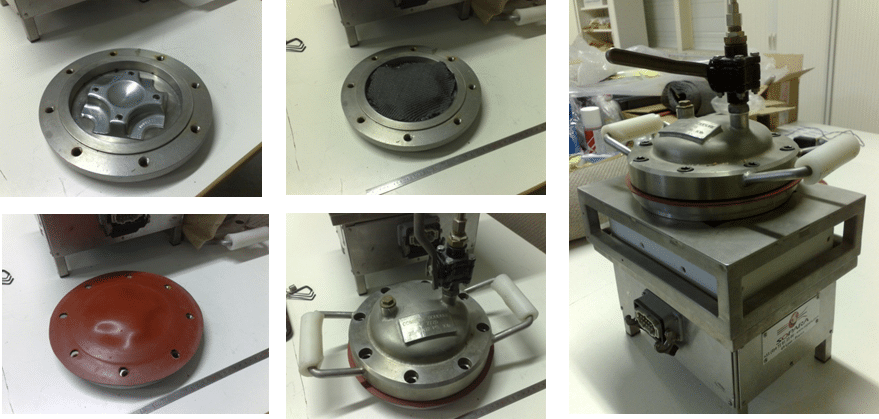

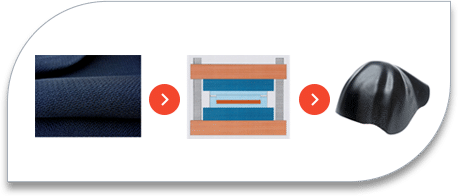

Consolidation techniques : different ways exist