Thermostatic tpfl

An innovative product to be promoted

The TPFL® are dry prepregs made from slivers or yarns which combine in an homogeneous way reinforcing fibres and thermoplastic fibres (carbone/PA12, carbone/PEEk…).

Proposed on different forms, braids, UD, 2D and non-crimp multiaxial fabrics, they constitute a suitable preform to rapidly mould advanced composite parts.

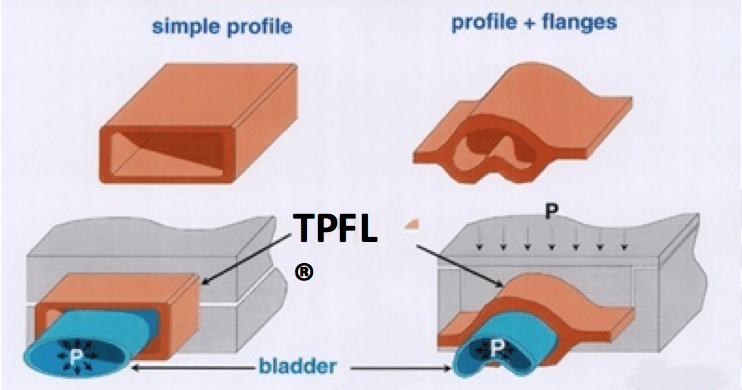

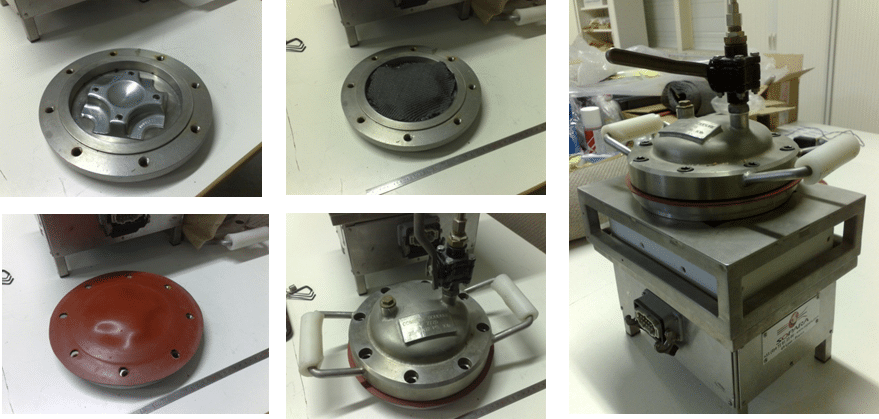

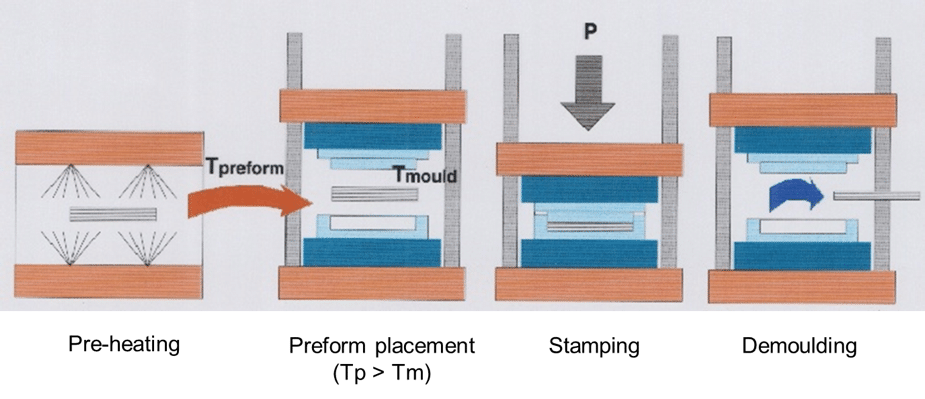

The moulding systems which can be associated with the TPFL® are : compression, L.I.M. (Bladder Inflation Moulding), stamping, membrane forming, induction, Carbone Forgé® system…

Technical apsects

Strengths

- Ease and short working process

- High mechanical properties

- Very low void content (<0,2%)

- High drapability

- Lack of volatile organic

- Recyclable

Raw materials used

- Carbone /PA12

- Carbone / PPS

- Carbone / Peek

- Aramid : PA12

- Preox

- Carbone

Applications

- Industrial

- Sport & leisure

- Aerospace

- Medical