technical yarns

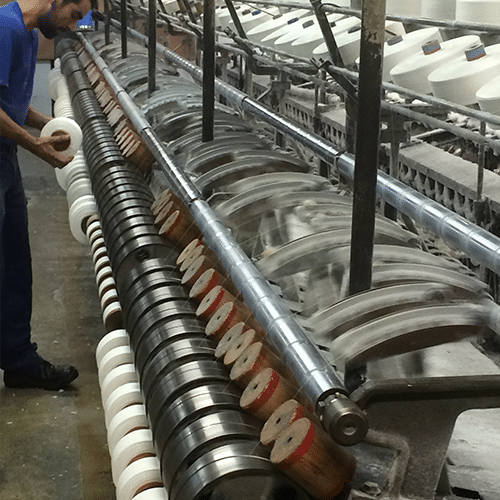

Schappe’s manufacturing process consists in the conversion of filaments into long-fibres resistant spun yarns combining different materials.

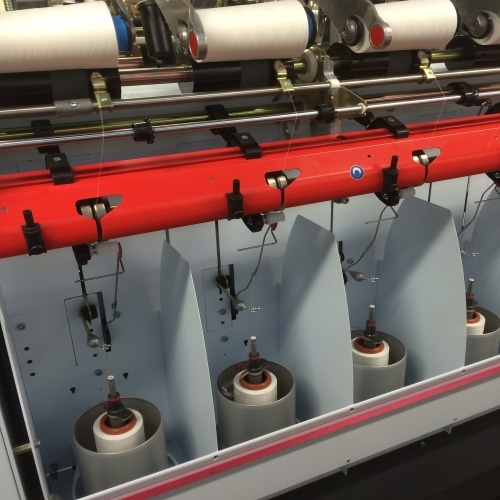

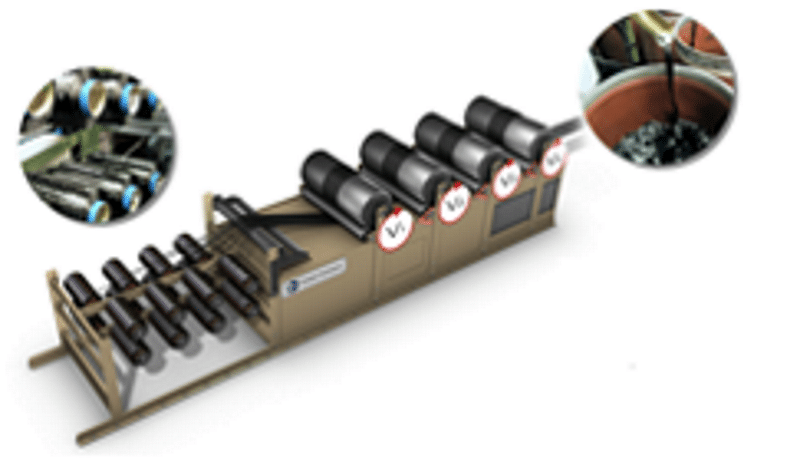

It relies on Schappe’s unique stretch breaking technique whereby a long continuous filament is successively stretched and broken to remove weak points and transformed into fragmented but resistant and regular yarns.

This unique stretch breaking technique provides significant advantages compared to other spinning techniques:

- It is suitable for a large range of raw materials, including the most resistant (carbon, aramids, stainless steel, polyethylene HT…)

- It ensures a predictable and consistent quality

- It improves the fibre’s technical properties

- It is suitable for the manufacturing of ultra-thin threads

- It allows material intimate blending

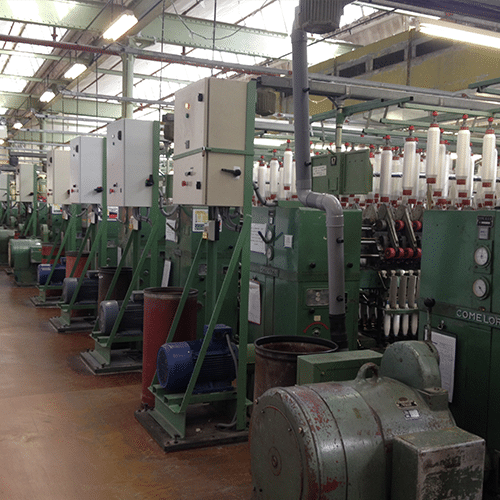

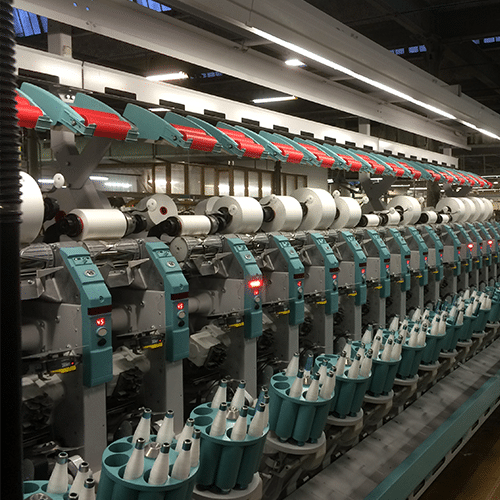

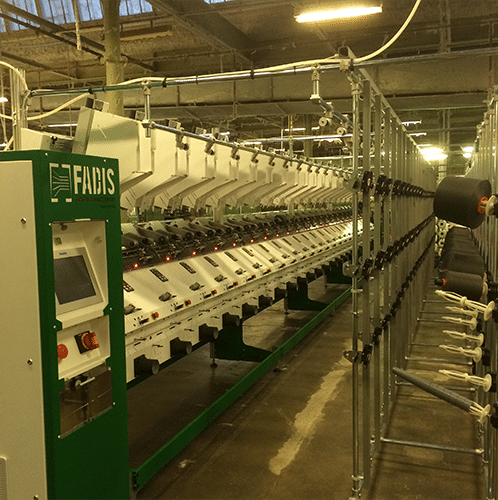

Schappe supports the entire manufacturing processfrom stretch breaking to final presentation of yarns, including: fibre blending, yarn colouring and dying, yarn winding and yarn weaving or braiding

Schappe’s technology key differentiating factors are:

- The largest and most innovative stretch-broken product offering on the market

- Consistent quality and strength

- Extensive yarn and material blending capacity

Process

Schappe develop special machines to offers new capabilities

Our know-how is clearly in the stretch breaking and in the finishing (singeing, scraping, manual splicing )

Have a look on the 11 steps of the process