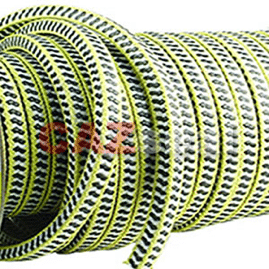

Packing Braid

Principles

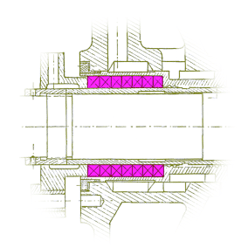

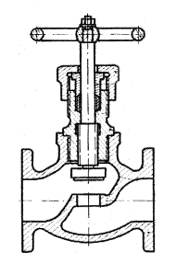

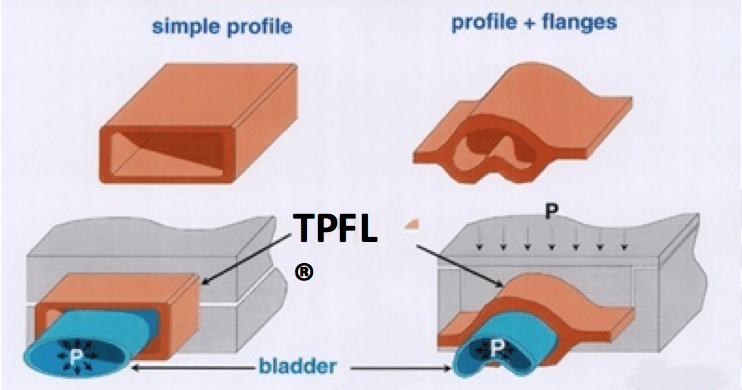

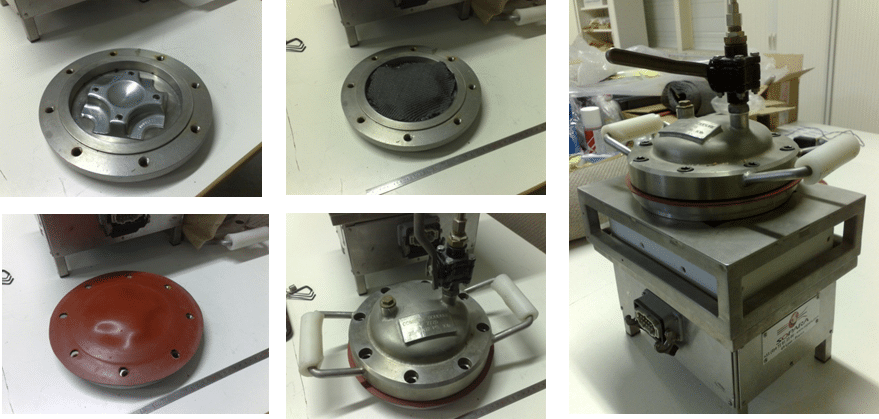

Packing function made in dynamic conditions for rotating pumps or turning machines, and in static conditions for valves or taps, is ensured particularly by a compressed braid in a stuffing box. Joint packing is a deformable material which must prevent or control fluid passing between surfaces in relative movement, one towards the other.

Technical aspects

End use

- Rotating and alternatives pumps, in general turning machines

- Valves and taps

Raw materials used

- Para-aramid

- Para-aramid / viscose

- Preox

- Carbone

- Carbone / Inconel

Fibres choice

To make these braids, Schappe offers a wide range of dry or coated yarns, depending on the conditions of utilization. Generally, the choice of components will result from the following requirements :

- Mechanical resistance

- Temperature resistance

- Thermal conductivity

- Lowest friction coefficient

- Chemical inertia

- Lowest dilation coefficient

Advantages

The fibrous structure of Schappe spun yarns is perfectly suited for these type of applications for several reasons :

- The ability for coating the braid is improved. Water-proofing is then better and the friction between the braid and the shaft is decreased.

- The elastic behaviour of the braid is increased which contributes to ensure a better packing.

- The possibility to mix different types of fibres.